AEROTOP® L

Air-to-water heat pump

Power 50.4 kW to 83.7 kW

Dencam Factory in Faaborg + Stenstrup, Denmark.

Dencam wanted to go “green” on heating their production halls, and either completely or partially displace their natural gas consumption with green electricity. Stable and constant heat was required to ensure homogeneous and uniform hardening in their production. There MUST be a constant temperature in the production halls, no matter the changes in outdoor temperatures. It’s a precondition for the moulding process.

Commenting on the project, Jens Anderson, CEO at Dencam, said: “When we chose ELCO as the product and TR VVS and Gastech-Energi as suppliers, it was due to price, quality and, above all, reliability. ELCO is a well-known and reputable European provider, and we've known TR VVS & Energiteknik for many years, so the choice was quite easy. And, so far, it seems like we have reduced the heating bill by 70% compared to before. Not bad.”

AEROTOP® L88 heat pumps use the ambient air as an energy source, providing a sustainable solution within a heating system, highlighted by their A++ energy class.

The AEROTOP® M and AEROTOP® L heat pumps have many advantages in commercial applications.

• Reduces global warming potential (GWP) by 70%

• Up to 4 heat pumps can be hydraulically interconnected

• ECO mode was developed to achieve maximum energy savings

• Forget about noise levels with a high- quality insulated construction and anti- vibration kits supplied as standard.

• Provides highly efficient heating and cooling all year round

• Faaborg: 2 x AEROTOP® L88 (installed in cascade)

• Stenstrup: 2 x AEROTOP® L88 (standalone)

Faaborg:

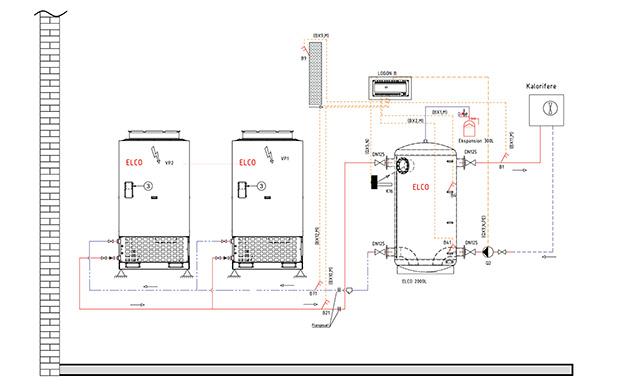

In Faaborg the heat pumps run in a traditional monovalent cascade solution, consisting of 2 x L88 coupled to a 2,000L buffer tank, with an inbuilt 45kW electric rod. Since the old heating system was air-born, new fan coil heaters have been installed in the production hall.

Stenstrup:

In Stenstrup the main production hall (110 x 30m), has heat pipes coming in at both ends, from the old gas boiler room. The heat system is divided in two, with one AEROTOP® L88 installed at each end, with a 1,500L buffer tank. Instead of an electric rod to provide backup and monovalent operation, the Logon B controller opens a valve letting the old gas boilers supply the extra heat needed below the bivalent point. In the future, should the area be required to run solely on electricity, it is possible to retrofit an electric rod in the buffer tank, provided that the necessary current is available.

AEROTOP® L88