Powered by quality

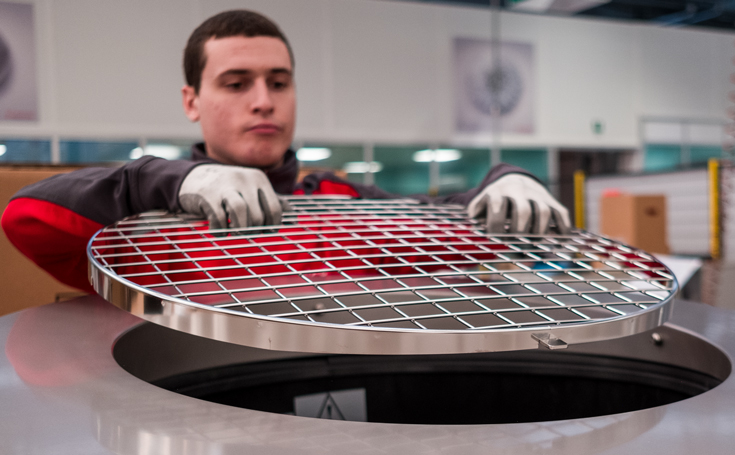

HEX3 is the proprietary heat exchanger at the core of our combustion technology. It is utilised across our entire premium gas boiler range – from the largest commercial models to our domestic units.

Featuring a multi-pipe construction, the heat exchanger helps achieve a high condensation rate even at full load, returning the highest levels of efficiency.

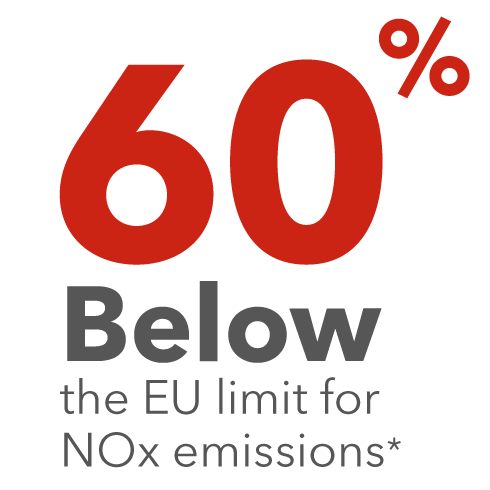

The HEX3 configuration also results in significantly lower NOx emissions, with ELCO’s products performing 60% below the EU NOx limit on average.

*The annual NOx emissions of ELCO PREMIUM gas boilers are up to 68% below EU limits. Average level for products sold is 22mg/kW.