TRIGON® XL

Gas condensing boiler floor-standing

Power 35 kW to 570 kW

10 Upper Bank Street in London, United Kingdom.

Comprising 30 occupied floors, four basement floors, special function suites, as well as a gym, swimming pool and auditorium – all spanning over 1 million sq. ft. – 10 Upper Bank Street required a modern, reliable and high performance heating system to cope with the fluctuating demands of the building.

Comment

The refurbishment of the plant rooms was managed by the Projects Department of Engie. Commenting on the decision to choose ELCO boilers, Project Manager, Tim Mardell, said: “We looked at a few products and narrowed it down to three, but it soon became clear that ELCO’s units were the preferred option for a numbers of reasons. Firstly, their ability to be disassembled into component parts allowed easy access in the restricted plant rooms. Secondly, the boilers’ performance easily satisfied several green issues for the project and, finally, the overall customer care offered was excellent.”

M&E consultants for the project were THD Consulting Engineers. Chris Glover, Director, said: “This was an ambitious project that required a carefully designed, high quality heating system. The ELCO boilers were chosen for a number of reasons, but one of the most important was their high levels of sustainability. I was really impressed with their overall performance, as well as the extremely low NOx levels on offer, so I will certainly be considering them for other projects.”

The TRIGON® XL represents a significant step forward in heating technology.

With extremely flexible configurations, clever design and a range of models available, the boiler is perfect for a variety of commercial applications. Plus, extensive cascade arrangements of up to 8 boilers with a combined output of 4,560kW are possible.

• Unique heat exchanger with HEX³ geometry for class leading NOx and CO emissions

• Extremely high efficiency

• Robust stainless steel heat exchanger

• Low water content boiler

• Compact dimensions

• Can be easily dismantled and reassembled onsite

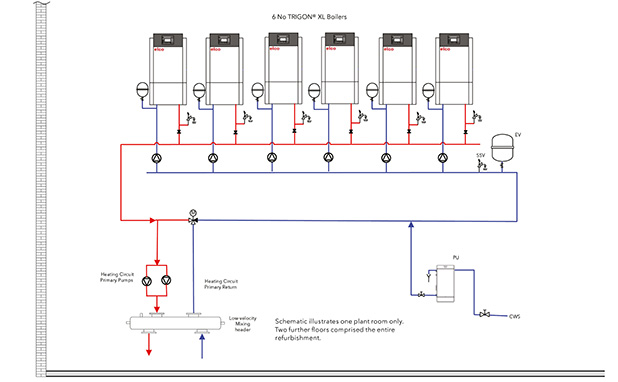

• 6 x TRIGON® XL 570 (in 3 different plant rooms)

To fulfil the system requirements, ELCO’s floor standing units were installed over three floors; four boilers on the 31st level, and an additional 11 divided between the fifth and sixth. ELCO also ensured hassle free integration to the building management system, by utilising the ELCO Commercial Gateway to allow communication via BACnet protocol.

"The entire installation process was straightforward, especially when it came to fitting the boilers in the required cascade arrangement within each plant room. The units are fantastic from an accessibility point of view, which will be particularly beneficial when it comes to annual servicing and maintenance. I was impressed with the smooth process of assembling them in situ and would highly recommend using them on future projects."

- Bob Masiero, Senior Projects Manager at HEVENTA Building Services Engineering (the M&E contractor for the project)

ELCO TRIGON® XL 570

* (EN15502)

** (In accordance with Equation 2 in the Non-Domestic Building Services Compliance Guide)